The application of 3D printing in the textile and fashion industry is rapidly developing, providing new solutions to old issues such as overproduction, waste generation, and limited design possibilities. One of the significant potential advantages of this technology is its ability to help sustain the environment.

This article explores how 3D printing can create reusable textiles by examining its advantages, present applications, and future.

Introduction to 3D Printing in Textiles

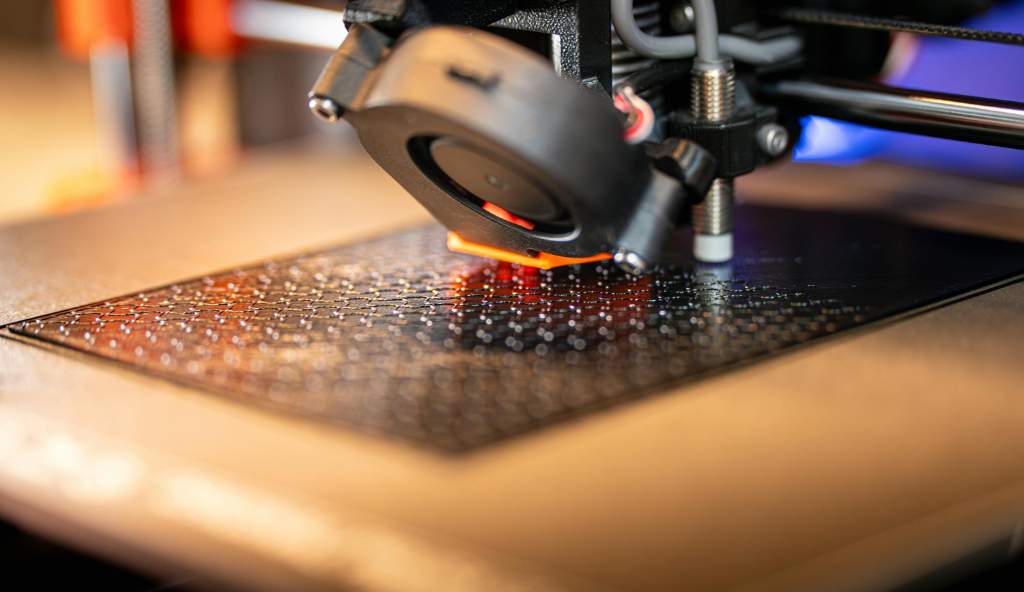

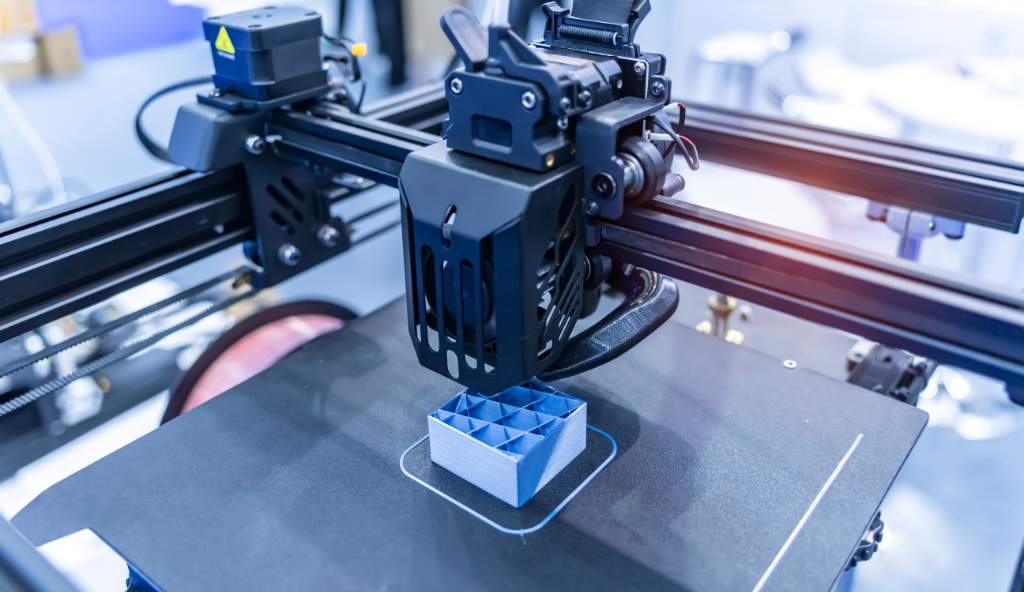

3D printing, also known as additive manufacturing, is a revolutionary process that involves the creation of 3D objects layer by layer using a digital image. This transformative technology has reshaped several industries, including automotive, healthcare, aerospace, textiles, and fashion.

3D printing has also made significant progress in the textile and fashion industries in the past few years. 3D printing can produce more sustainable textiles by controlling material usage and design.

Advantages of 3D Printing for Sustainable Textiles

Reduction of Waste:

Traditional textile manufacturing processes often result in significant waste from cutting patterns from large fabric rolls. However, 3D printing, with its layer-by-layer approach, minimizes material wastage. This additive manufacturing process has the potential to significantly reduce textile waste, offering a hopeful outlook for a more sustainable production cycle in the fashion industry.

Efficient Use of Resources

3D printing only allows the exact application of materials when needed, maximizing. This accuracy reduces the consumption of energy and raw materials and further reduces the carbon footprint of the production of textiles.

Customization and On-Demand Production

3D printing allows the production of custom-made clothing and textiles that are tailored to specific dimensions. It can help reduce excess production and inventory that isn’t sold, essential issues in the traditional fashion sector. On-demand production can reduce large storage spaces and transportation requirements, resulting in a lower carbon footprint.

Innovative Materials

The advancements in 3D printing technology have led to the development of eco-friendly materials. Biodegradable polymers and recycled plastics are possible in 3D printing, providing environmentally friendly alternatives to conventional textile fibers.

Current Applications of 3D Printing in Sustainable Textiles

Eco-Friendly Fashion Lines

Many fashion brands and designers are leading the way in using 3D printing to produce eco-friendly collections. For instance, designers like Stella McCartney have explored 3D-printed clothes made from sustainable materials and techniques.

Recycled Materials

3D printing permits the recycling of plastics and other materials to make new textiles. Companies such as Adidas have launched products like Futurecraft Loop, Futurecraft Loop, a fully recyclable performance shoe made of 3D-printed components.

Innovative Fabrics

3D printing can create new types of textiles with distinctive characteristics. These unique fabrics can be developed to last longer, which means less frequent replacements, thereby reducing the overall environmental impact.

Challenges to Overcome

The potential of 3D printing to help create sustainable textiles is vast, but several issues need to be addressed.

Material Limitations

The variety of materials suitable for 3D printing on textiles is currently restricted. More research and development is necessary to increase the variety of eco-friendly fabrics that can be utilized.

Cost and Accessibility

Presently, the price of 3D printing equipment and materials is prohibitive for certain manufacturers. Making the technology accessible and affordable is vital to ensure widespread adoption.

Technical Expertise

The application of 3D printing on textiles demands exceptional understanding and expertise. Education and training in this field must be improved to allow more manufacturers and designers to utilize this technology effectively.

Future Prospects

The future of 3D printing to create sustainable textiles is promising, thanks to the constant advancements in materials and technology:

Biodegradable Polymers

Research is currently focused on creating biodegradable materials specifically made to print in 3D. These polymers can be broken down naturally, reducing textiles’ environmental impact.

Circular Economy Models

3D printing is essential in circular economic models where the products are made to be remanufactured, reused, or recycled. Allowing upcycle and recyclable textiles to be produced through 3D printing can help create an environmentally sustainable life cycle for fashion-related products.

Mass Customization

As 3D printing technology becomes more advanced and cost-effective, mass customization of clothing and textiles will become feasible. This approach can significantly reduce waste and overproduction, aligning with sustainable production principles.

Mass customization of clothing will be possible when 3D printing grows more sophisticated and cost-effective. This method can drastically reduce the amount of waste and excess production and is in line with sustainable production methods.

3D printing is a promising technology that can create sustainable textiles for the fashion industry. This process can bring many environmental advantages by decreasing consumption, maximizing resources, enabling demand production, and encouraging new materials development by CountDeals.